Autonomous Hexapod w/ Computer Vision

The Team

Shawn Victor - Project Manager/ Mechanical Systems Lead

He will be our project manager, responsible for dividing up the work and act as a systems engineer for this hexapod. He will also double as the main mechanical engineer of the project, CADing up the whole robot prior to the competition and have the parts printed/laser cut during the competition.

Rita Kambil - Software Engineering Lead

She will be responsible for leading the development of the general software layout. Her role is more so to coordinate between the two software engineers handling the full control of the servo motors to emulate fluid movement of the robot and the computer vision input software. She will be writing the code that bridges the movement with the control algorithms.

Shivani Gupta- Electromechanical Systems Engineer

She will be responsible for working with the Mechanical Systems Lead to design and manufacture the parts to create the mechanical system. This will require 3D printing all the parts and making modifications to the parts to ensure fitting. She will also design the E-chassis of the robot to ensure proper mounting locations for the wiring harness.

Sijin Woo- Electromechanical Systems Engineer

Responsible for the testing and debugging of the electrical hardware to ensure proper working condition. He will also aid in the process of manufacturing the parts for each arm with Shivani.

Zee Lv- Software Feedback Controls Engineer

Responsible for designing the software the will interface with the computer vision camera selected, and from that data be able to coordinate with the Controls Engineer to effectively use this data to move the robot accordingly. This will require the use of body detection and color detection with the Pixy Cam.

Corey Hulse- Software Controls Engineer/ Electromechanical Systems Engineer

Responsible for designing software that will allows for seamless integration of any input control to the hexapod and allow for easy servo actuation that models the movement of the robot. Will also be responsible for aiding in the process of manufacturing the parts of the hexapod.

He will be our project manager, responsible for dividing up the work and act as a systems engineer for this hexapod. He will also double as the main mechanical engineer of the project, CADing up the whole robot prior to the competition and have the parts printed/laser cut during the competition.

Rita Kambil - Software Engineering Lead

She will be responsible for leading the development of the general software layout. Her role is more so to coordinate between the two software engineers handling the full control of the servo motors to emulate fluid movement of the robot and the computer vision input software. She will be writing the code that bridges the movement with the control algorithms.

Shivani Gupta- Electromechanical Systems Engineer

She will be responsible for working with the Mechanical Systems Lead to design and manufacture the parts to create the mechanical system. This will require 3D printing all the parts and making modifications to the parts to ensure fitting. She will also design the E-chassis of the robot to ensure proper mounting locations for the wiring harness.

Sijin Woo- Electromechanical Systems Engineer

Responsible for the testing and debugging of the electrical hardware to ensure proper working condition. He will also aid in the process of manufacturing the parts for each arm with Shivani.

Zee Lv- Software Feedback Controls Engineer

Responsible for designing the software the will interface with the computer vision camera selected, and from that data be able to coordinate with the Controls Engineer to effectively use this data to move the robot accordingly. This will require the use of body detection and color detection with the Pixy Cam.

Corey Hulse- Software Controls Engineer/ Electromechanical Systems Engineer

Responsible for designing software that will allows for seamless integration of any input control to the hexapod and allow for easy servo actuation that models the movement of the robot. Will also be responsible for aiding in the process of manufacturing the parts of the hexapod.

Abstract

This project was inspired by some online videos in which people created their own spider like “Hexapod robots” that utilized multiple high torque servo motors to actuate control of each of the appendages of the robot. Separate of those videos we were interested in using off the shelf computer vision cameras like the Pixycam to add as an input into our feedback loop in order to control movement. What we are aiming for our end goal of this project is to have fully assembled the Hexapod, test full control over our bot, and to implement our control algorithm with the camera.

Why did we build it?

The way we are going about designing our Hexapod is to have it not only mimic the movement of Hexapod insects, but also provide it the means up interacting with its surrounding environment. Those interactions take the form of computer vision analysis and autonomous movement. We are aiming to have our Hexapod be able to track human motion and follow the person in front of it.

Why is this Significant?

While Hexapod are in no way a new concept and are even commercially available at this point, most of these produces do not have any autonomous control systems in place. Rather these solutions utilize remote controls in order to control the motion of the robot. Our proposed solution targets autonomous motion through the use of computer vision as well as many other on board sensors. Our project also incorporates WiFi control using an ESP-12 so it can switch between autonomous and manual control.

What is Technically Challenging?

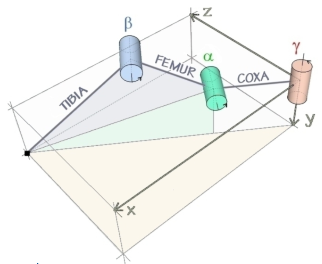

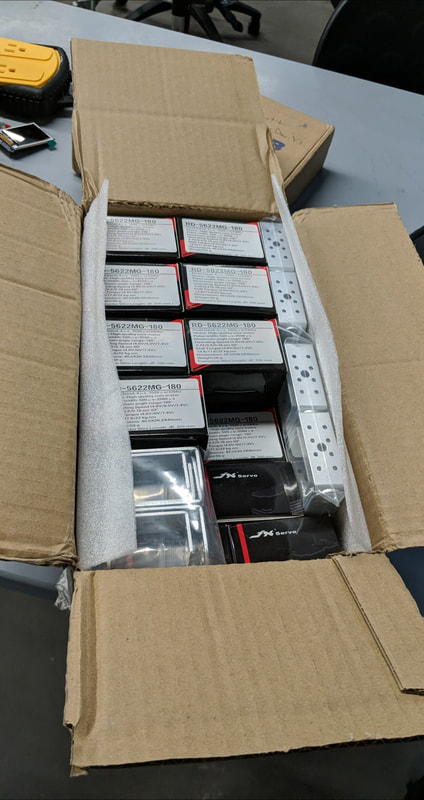

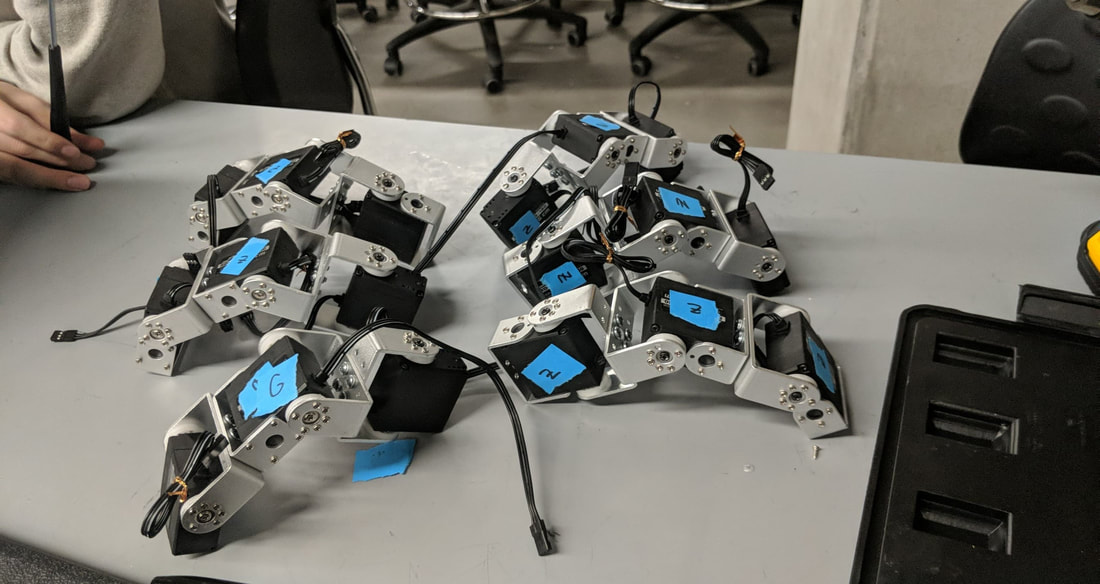

Given the level of abstraction we are seeking to apply to this Hexapod each subsection of it holds its own challenges. From a mechanical perspective, we need to design a robust and rigid chassis as well as an armature system to handle the distributed weight of the E-chassis. Another mechanical challenge is in terms of designing the models to get the kinematics that model Hexapod insects. From an Hardware electrical perspective, the challenge is being able to properly handle to stringent power requirements of each of the motors and making sure adequate measures are taken to prevent components from frying during the testing phase. A bulk of the challenge from this project will come in the form of software and developing the code as well as algorithms to produce the exact kind of results we are looking for. Computer Vision in no way is a simple task to implement in a project, but the developed hardware and software libraries the PixyCam offers will at least handle a large portion of that issue. However, probably the most challenging part of this will not be technical, it comes in the form of managing our time and effectively tasking out work and thus increase our work efficiency. Projects like this normally would require large amounts of time to properly design, test, and develop. Given our timeline this will prove to be quite the challenge.

The Design

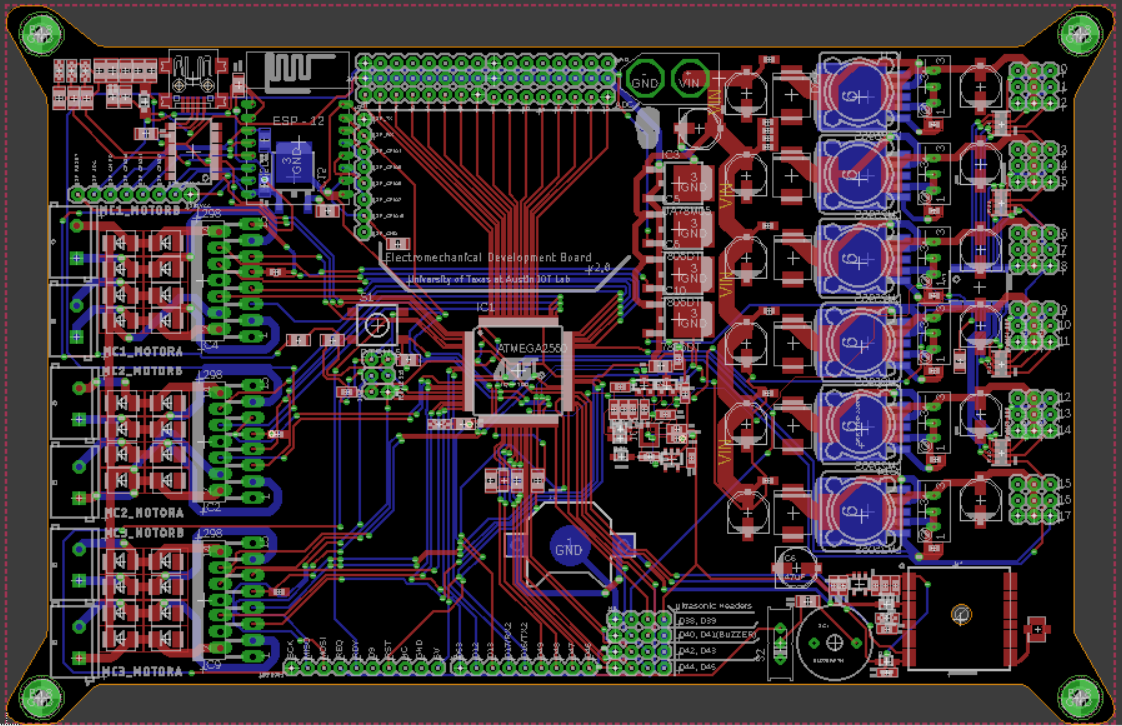

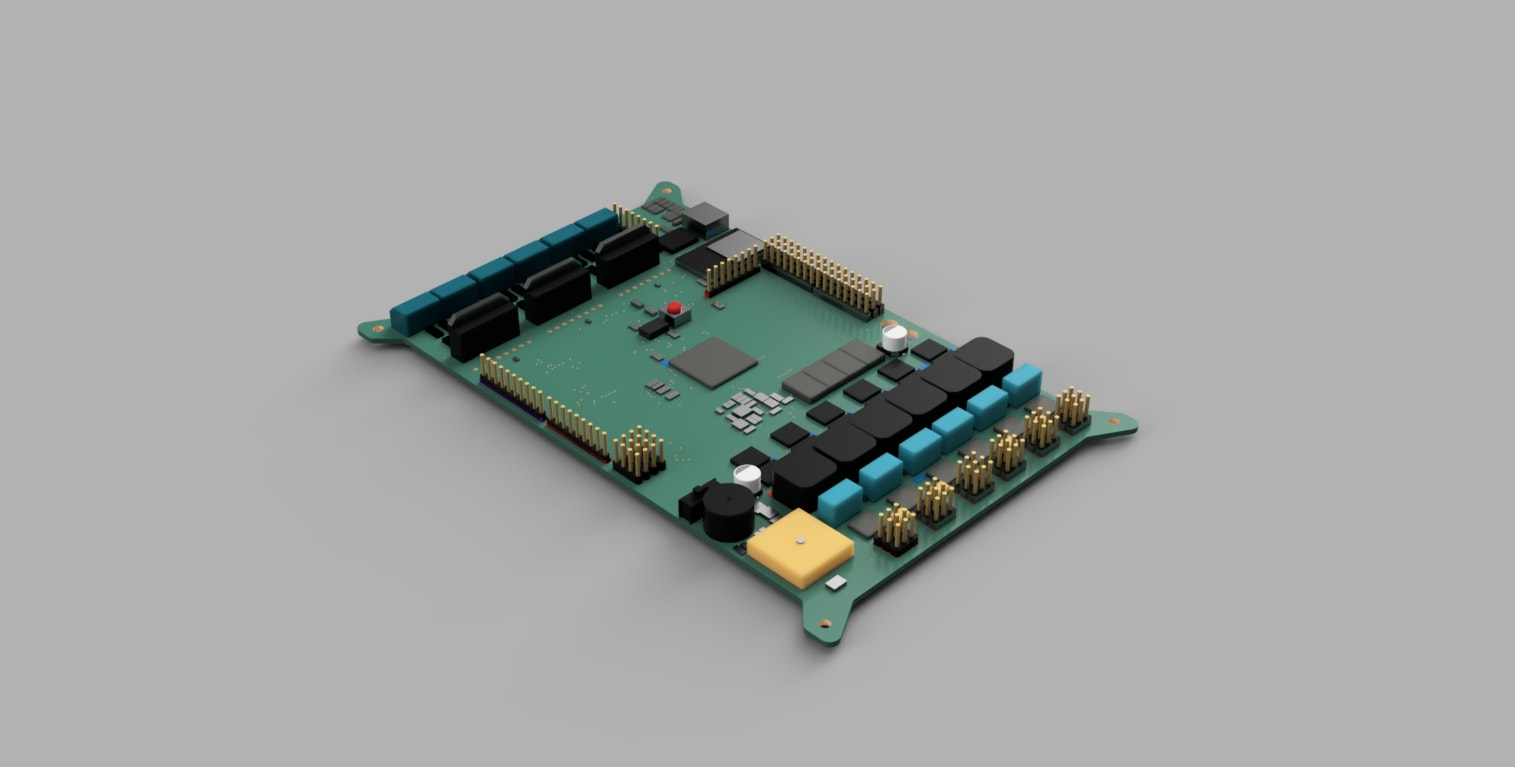

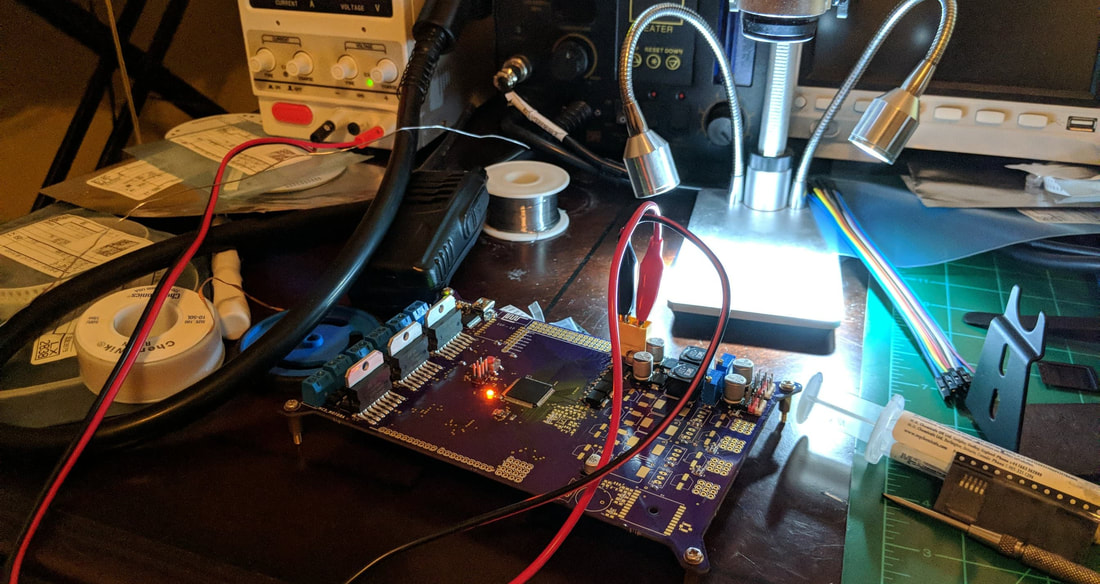

Electronics

The design of this Hexapod started out with one of my previous projects I do under my "Research" Tab, known as the Electromechanical Development Board. This will be the main brains of this whole project, and show off just how robust this board is for any sort of robotics project. We start with the development of the Schematic:

Your browser does not support viewing this document. Click here to download the document.

Your browser does not support viewing this document. Click here to download the document.

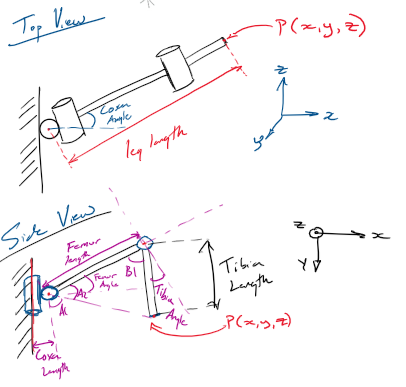

Mechanical

|

|

|